Stamping & Assemblies for the Filtration Industry

At Varbros, LLC, customers have counted on us for over 50 years to provide exceptional quality stampings and assemblies. We offer stamping services with a wide range of stamping presses, handling anywhere from 100 to 1,100 tons. Our stamping services are available for prototypes, full production, and contract manufacturing. We supply our services to tier 2 and tier 3 companies, along with offering just-in-time inventory services.

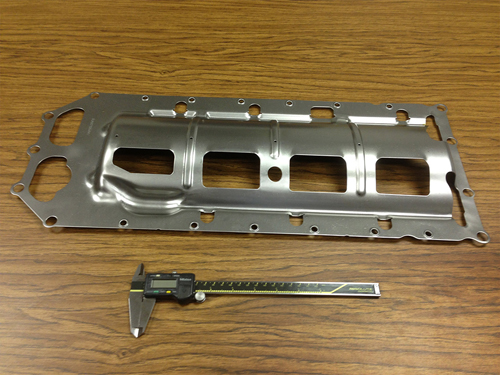

At our 188,000 square foot facility, we can accommodate materials including carbon steels, high-strength steels, pre-coated steels, aluminum, and tin plate. We stamp these materials in thicknesses that range from .015” to .315” – manufacturing to tolerances as tight as ± 0.001”.

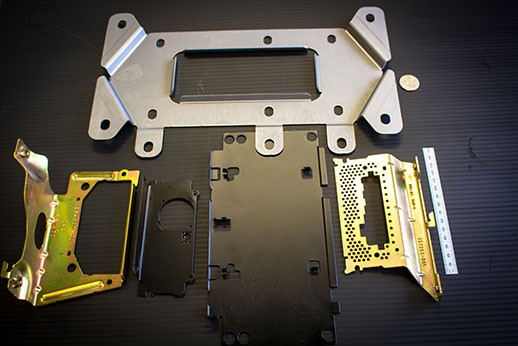

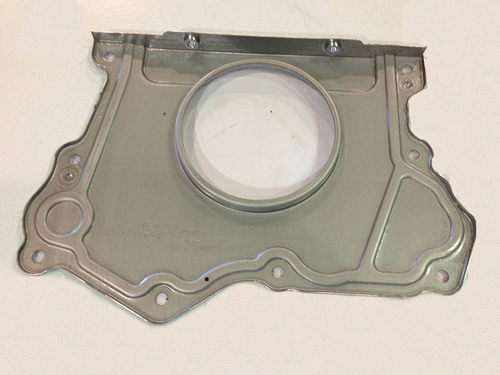

Full assembly services are also available, including high quality projection, resistance, and spot welding. We provide our stamping and assembling services for industries such as the filtration industry providing products such as nut plates, retainers, and welded assemblies. The quality of our work is demonstrated by our ISO 9001:2015 certification with efficiency programs including lean manufacturing and a Six-Sigma Black Belt on staff.

We back up our stampings and assemblies with a variety of additional services, including post-plating and coating, deburring, heat treatment, tapping, CNC machining, and more. The multiple varieties of manufacturing services we provide make us a one-stop shop for many of our customers for high volumes production.

For further information about out stamping and assembly services, please see the following table or contact us directly.

Custom

Production

Just-In-Time

Tier 2 & 3

This method uses a solid projection in the material to concentrate the current flow at a contact point which results in lower currents, forces and process times than spot welding.

A process where heat is generated by passing current through the resistance caused by the contact between two or more metal surfaces to be joined.

A form of resistance welding used to join overlapping metal sheets. Two electrodes are used to clamp the sheets together and pass the current between them.

High-Strength Steel

Pre-Coated Steel

Tin-Plate Steel

Aluminum

Rear Retainers

Nut Plates

Welded Assemblies

Post-Plating & Coating

Deburring

Heat Treatment

Welding

CNC Machining

Metal Stamping

High-Volume Runs

Contract Runs

Automotive

Appliance

Building Products

Medical

IATF 16949:2016

Practice Lean Manufacturing Principle

Black Belt

Catia (CATDrawing, CATPart)

IGES — Initial Graphics Exchange Specification, ANSI file format

MasterCam (MDX, MC8, MC9, SET)

STEP — Standard for the Exchange of Product Model Data